It is with great enthusiasm that we announce the arrival of an important event that will be held at the Piacenza Expo exhibition center from the 5th to the 7th October 2023: an extraordinary opportunity for industrial sector enthusiasts.

GIS the special event awaited by the world of lifting equipment and machinery

Preparations are underway for the 9th edition of the GIS-Italian Days of Lifting and Exceptional Transport. It is now certainly the largest European exhibition-conference dedicated to the relevant product sectors.

GIS the special event: an announced success

The 2021 edition recorded an extraordinary participation with exhibitors from various parts of Italy and Europe. Therefore, after this success, GIS rightfully stands as a unique place for sharing experiences and discovering the latest innovations in the sector.

According to Fabio Potestà, Director of Mediapoint & Exhibitions, as well as organizer of the GIS, the 2023 event promises to be even more grandiose, also thanks to the full use of the conference facilities available at Piacenza Expo. A relevant opportunity, considering that numerous requests for participation from foreign companies are already confirmed, strengthening the position of this event as the largest trade fair-conference in the sector in Europe.

The event will continue to benefit from the support of the main Italian and foreign sector associations, as well as the country’s institutional bodies.

GIS the special event and more… “GIS by Night”!

But there’s more! This year there will be something really special: “GIS by Night”! A special event scheduled for October 6th, which will stand out for the extraordinary evening opening of the entire fairgrounds. This opportunity will allow exhibitors and their guests to establish professional connections and socialize, while they can taste a wide selection of gastronomic delights and drinks distributed throughout the fairgrounds.

The distribution of food and drinks for the “GIS by Night” will begin around 7.30pm, immediately after the ILTA 2023 awards ceremony. This year, the ceremony will take place in the adjacent Pala Banca, starting at 6pm.

Access to the “GIS by Night” event will only be allowed to holders of a dedicated ticket.

The staff in charge of distributing food and drinks during the “GIS by Night” will ask ALL participants to show their authorization badge before providing the corresponding service.

Click on the link for more info!

GIS the special event and Tamarri is there!

We at Tamarri S.R.L. We are waiting for you with lots of news!

We will be happy to show you:

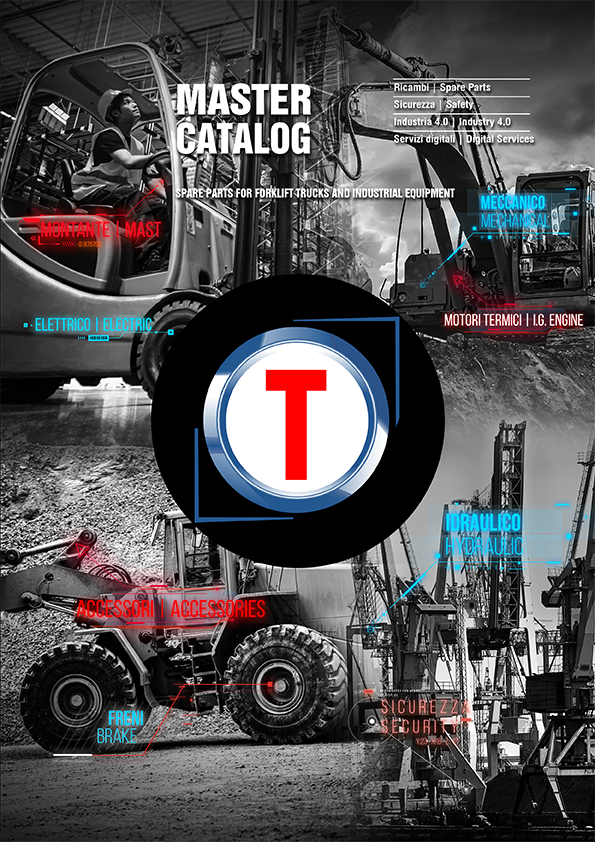

👉 The new Product Catalog with over 100,000 items delivered in 24/48/h.

The SAFETY and DIGITAL SERVICE Catalogue, the innovative devices to improve safety in warehouses and increase productivity.

Technology is a must at Tamarri S.R.L: the main products

In the SAFE and SERVICE DIGITAL Catalog you will find a detailed description of Tamarri’s flagship items:

SMARTPASS EVO 4.0

The latest news from Tamarri!

SMARTPASS EVO 4.0, control the vehicle in the cloud. Born from careful research and collaboration with local digital entities, SMARTPASS EVO 4.0 is the new platform of Tamarri S.r.l. for complete control of the vehicle directly from the Cloud platform. Innovative, practical, safe and Industry 4.0 certified.

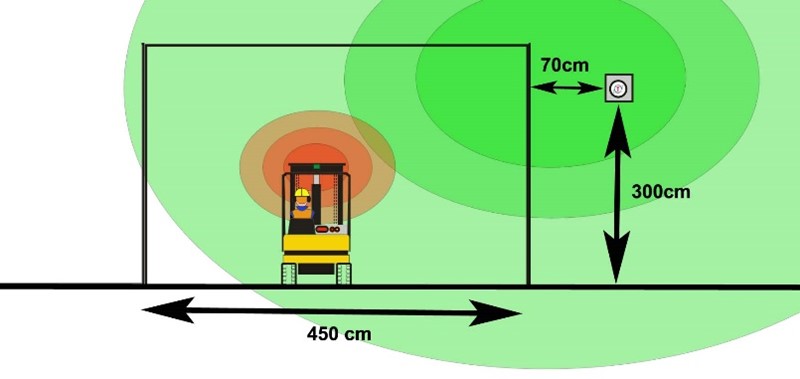

With the aim of improving the safety of the logistics sector on handling vehicles, from the warehouse to the construction site, SMARTPASS allows the recognition of the driver, the localization of a pedestrian or other moving vehicle near the forklift, the slowing down of the vehicle at interior of specific areas and the automatic opening of mechanical gates.

Furthermore, thanks to the real-time log system, SMARTPASS is able to record all events, transforming them into alerts that can be easily consulted through the dedicated SMARTPASS Cloud Service web portal.

SMARTPASS EVO 4.0 together with SMARTPASS Cloud Service, allows you to enable a vehicle simply by using the badge already in use in the company! It adapts to every industrial vehicle: from forklifts to agricultural and earthmoving vehicles. Furthermore, with SMARTPASS EVO 4.0 access and control of the vehicle have never been so simple and all thanks to the Cloud platform.

With SMARTPASS EVO 4.0, it is possible to control access to each vehicle and associate drivers with specific vehicles. Thanks to its versatility, the device allows the use of two technologies: RFID for use through your company badge or BLE, through wearable devices (pins, watches, etc.) with Bluetooth 5.0 technology.

This flexibility allows each company to choose the best solution to adopt within its own departments, both logistics and production. Thanks to the customization functions it is possible to enable operators for specific vehicles. Furthermore, the sophisticated log system records all events that can be consulted through the SMARTPASS Cloud Service portal.

STS

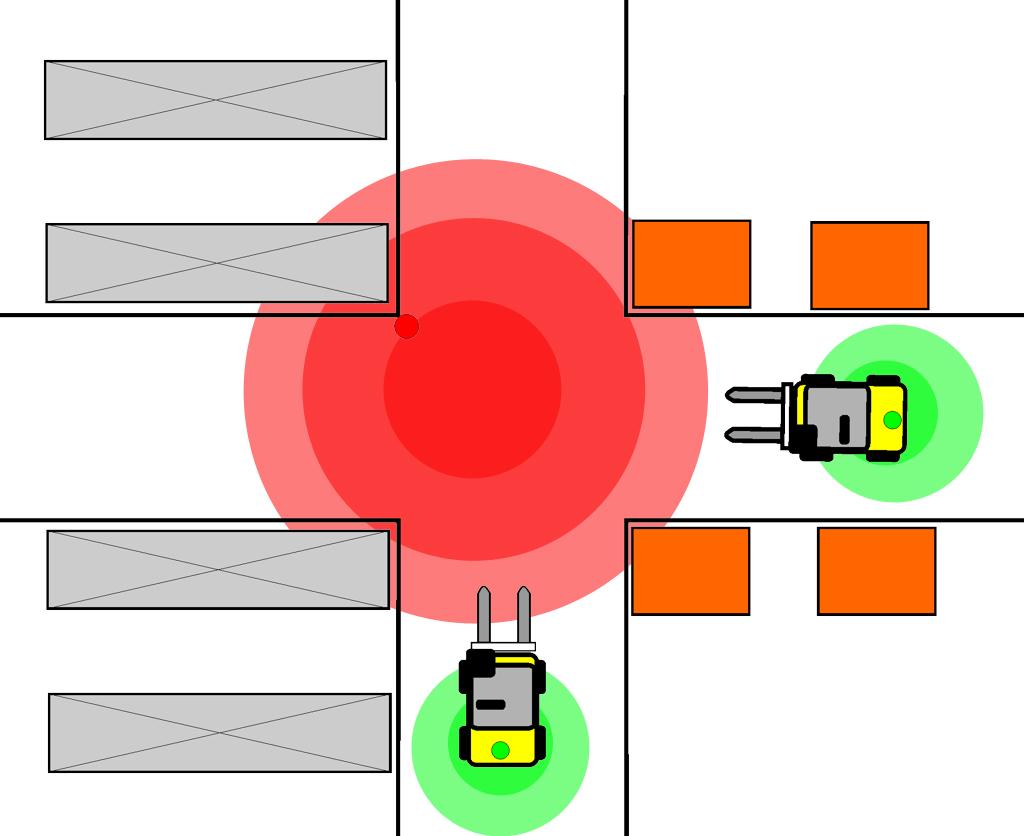

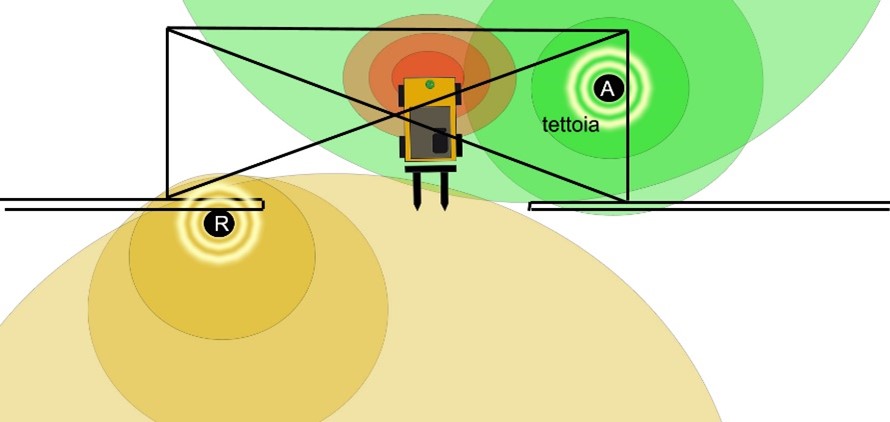

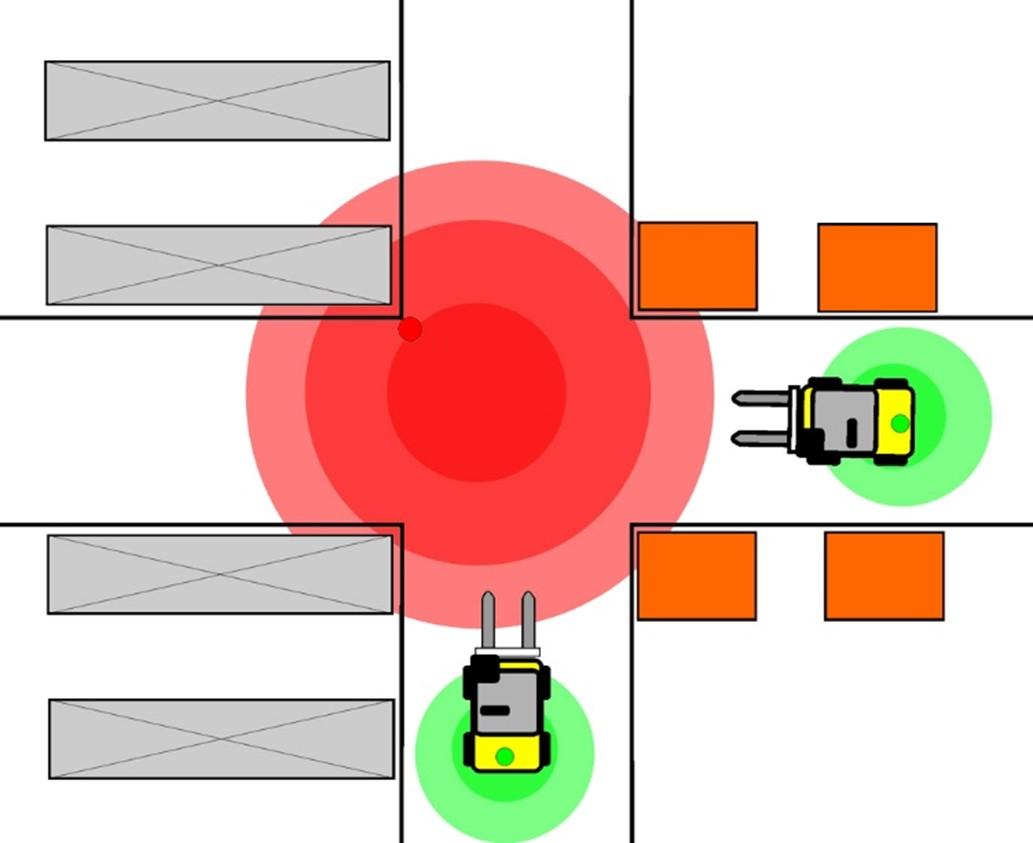

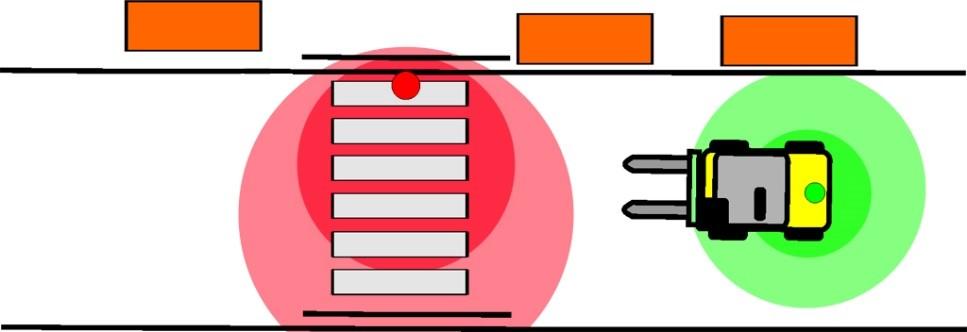

The platform which aims to improve safety in the logistics sector on handling vehicles, from the warehouse to the construction site. SafeTSystem allows the recognition of the driver, the localization of a pedestrian or other moving vehicle near the forklift and the slowing down of vehicles within specific areas, representing an excellent aid to the safety systems already adopted. It also allows you to record all events (management, driving progress, danger, collision) transforming them into alerts that can be easily consulted via mobile devices and internet browsers.

STS is very simple and feature rich. With STS it is possible:

Control access to the vehicle, for example enable drivers by associating them with specific vehicles so as to control access (Tkeylock function)

Check the presence of pedestrians in the vehicle maneuvering areas (Tsafe function)

Automate vehicle slowdown in specific areas (Tslow function)

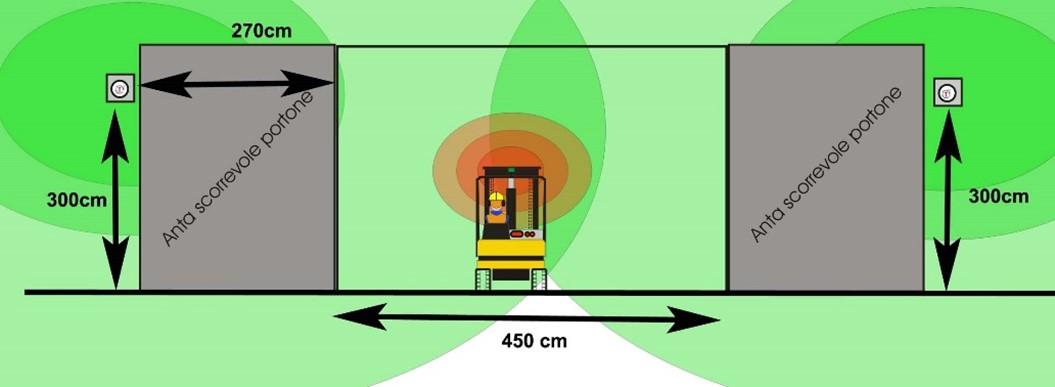

Automate the opening of unmanned mechanical gates (Topen)

Manage vehicle safety signs (such as red/blue lights, buzzers, sirens)

STS consists of several devices and transmitters and is extremely modular. The number of components varies based on the different security needs, the structure where the system will operate, and the functions you want to implement. The basic device identified with the name FORKLIFT DEVICE is the central hub of the system, used for the collection of signals, data and parameterization of the system. The other elements are:

DOOR OPENER DEVICE allows you to automate the opening of unattended mechanical gates, works in combination with the DOOR OPENER(r) transmitter

DOOR OPENERTRANSMITTER used in combination with the DOOR OPENER device allows you to automate the opening of unattended mechanical gates

SLOW AND ACCELERATE TRANSMITTERS allows you to automate the slowing down and normal speed of the vehicle in specific areas

DRIVER TRANSMITTERS can be worn and allow you to control access to the vehicle, for example by enabling a specific driver to use a specific vehicle. Works in combination with the FORKLIFT device

PEDESTRIAN TRANSMITTERS are weareable devices and allow you to check the presence of pedestrians in the vehicle maneuvering areas. They operate in combination with the FORKLIFT DEVICE

The entire system is managed with SafeTApp, the specific app created for Android® devices that allows you to parameterize:

- all devices and transmitters

- log check

- check events

Furthermore, it is possible to subscribe to the SafeTCloud subscription, the innovative cloud platform that allows you to centralize all data safely and reliably in a personalized and always accessible dashboard.

TRACKER EVO

The system derives from the GeoTsystem and the Tracker SS9009 device, to which functions and hardware modifications have been added. in addition to the 4.0 certification produced by Archita Eng., a leading and accredited company in the sector.

Due to the simplicity of installation and the low cost, SS9009K-EVO is particularly suitable for applications on: electric pallet trucks, brooms, scrubbers, aerial platforms, agricultural machinery, construction vehicles.

Main functions:

- Remote and real-time localization and tracking of vehicles.

- Access control, through the use of magnetic keys, which allows only employees authorized by the company to start the vehicles and track them.

- Remote vehicle lock (by managing the DOT1 output).

- Remote vehicle slowdown (by managing the DOT2 output).

- Collision detection by programming the event, simple alert on the portal. Possible actions: email to the manager, vehicle blocking or slowing down.

- Geofence: possibility of drawing a perimeter on Google maps outside of which a simple alert or an email to the manager can be sent to the portal, vehicle block or slowdown.

- Counting of hours of activity, for the management of scheduled maintenance.

- Data display via CAN (if made available by the manufacturer).

- Sending periodic reports.

😉 Come and visit us at GIS from 5 to 7 October 2023: we will be at PAD./PAV1 STAND C166 at the Piacenza Expo exhibition center (Via Tirotti 11, Fraz. Le Mose). 👌

🔗More info https://gisexpo.it/