Predictive maintenance: Machine Learning and Artificial intelligence for a successful maintenance politicy in the company.

Predictive maintenance and data-driven approaches

In the last decade, there has been a lot of talk about Machine Learning and Artificial Intelligence applications in the context of company maintenance policies, so that they are considered the panacea for all problems.

Over time it was understood that there is no better policy than others. As far as maintenance is concerned, in fact, every company must try to find the best strategy which often does not consist in a single policy, but in a mix of different and correct strategies.

Predictive maintenance: the evolution of maintenance strategies over time

In the past few years, the interest in maintenance has never been central to the CEO’s agenda. However, after the pandemic, more company managers are turning their interest to this aspect, which has now become important.

The reason is clear: in the Covid era, the critical points of companies emerged more clearly: fragility and corporate rigidity. Hence the need of transformation into flexible and strong companies able to withstand sudden crises and emergencies. Not only that: strong companies are above all those that in addition to withstanding the emergency, are also able to take advantage of it.

Maintenance is no longer just essential to support operational continuity, but also as a solution to ensure production efficiency. Adapting profitably and efficiently to rapidly changing contexts is now more fundamental than ever.

Predictive maintenance: maintenance policies

Maintenance policy and historical evolution of maintenance engineering go hand in hand. Both, then, follow the level of knowledge of the system.

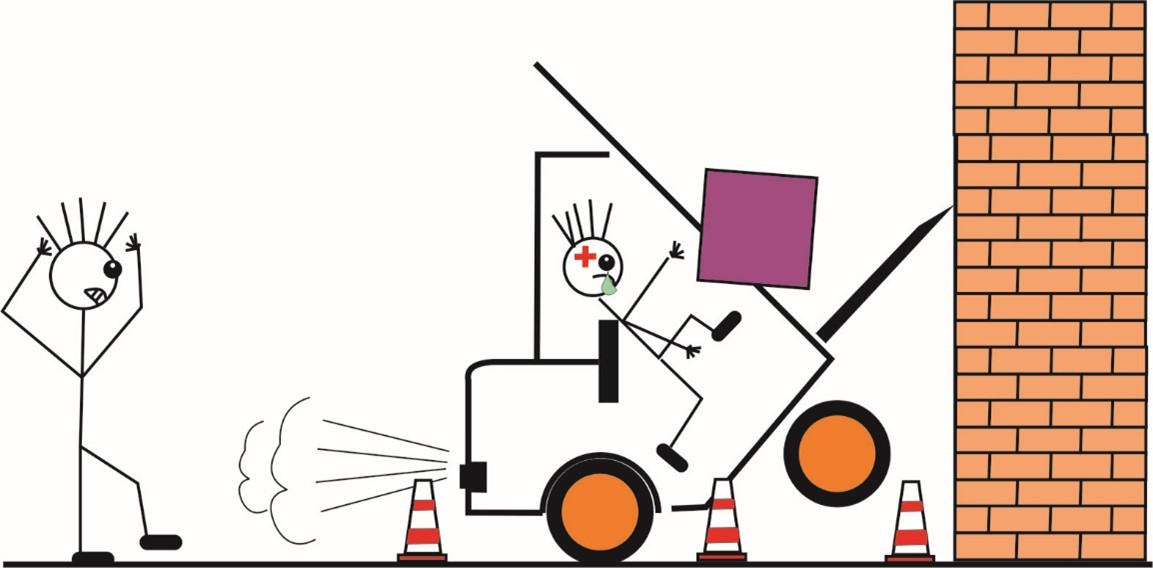

From corrective maintenance, which is not very effective for the efficiency of a plant, we have moved on to preventive maintenance on a statistical basis. That is the time to replace the component or system is established to avoid failure, which is based on the historical data collected and cost models. Of course, such a strategy is not suitable for accidental failures, but only for those due to wear.

In order to plan maintenance intervention in an economical and efficient way, the ability to collect health data of the plant following the various inspections and the ability to predict the remaining life is essential. Only by doing this is possible an effective maintenance policy.

Often these strategies are considered as maintenance cost reduction policies as their main objective is to avoid failure and minimize the impact on plant performance.

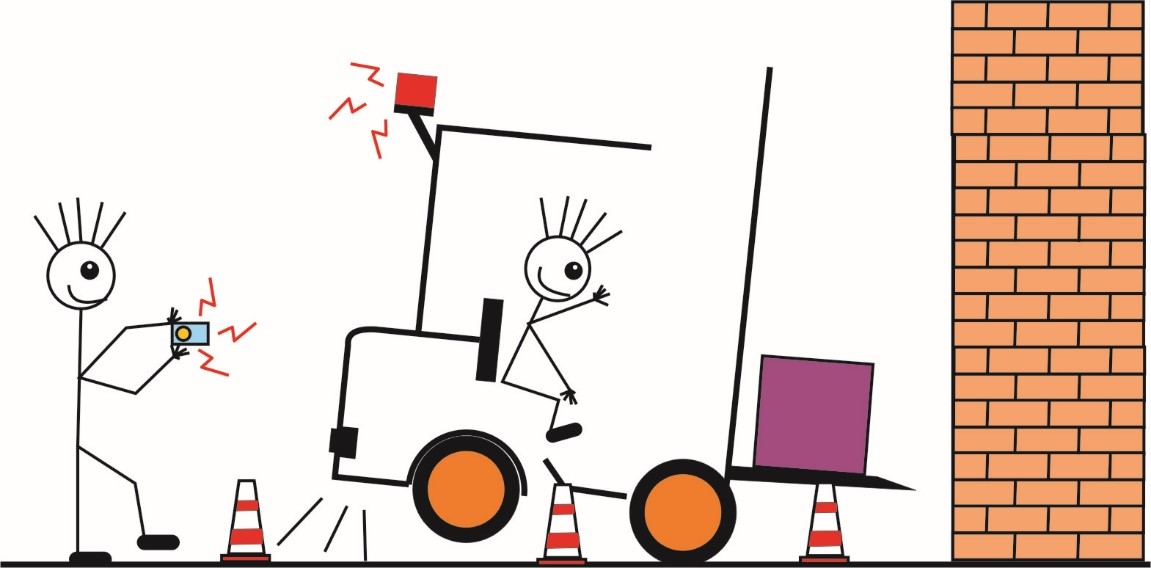

In recent years, many companies have understood the importance of investing in the acquisition of weak signals from systems, such as the current absorbed, the temperatures of the components, the variation in energy consumption and vibrations. All of this can be managed thanks to the advent of technologies such as low cost sensors and cloud computing. This is how we arrived at the new predictive maintenance policies.

Predictive maintenance: data collection and the right balance between predictive policies

For many years Predictive maintenance has been discussed and practiced. But it is thanks to increasingly high data collection capacity that predictive maintenance has been fully exploited.

What is the best way to generate profit? The first step is to proceed with a cost-benefit analysis. Without a doubt, corrective maintenance involves very low investments, but it can lead to very high costs for downtime or repair. In addition, there can be unpleasant cost consequences even for not predicting when the failure will occur.

Preventive maintenance, on the other hand, could lead to the inconvenience of a risky presumption of safety. Furthermore, this policy does not correspond only with artificial intelligence applied to maintenance. In fact, there are field predictive techniques and data-driven techniques.

Both are excellent strategies to promptly identify a malfunction, however, field predictive techniques are more effective in detecting mechanical defects. In addition, field techniques are less tied to historical data than predictive ones.

Therefore, the post-Covid scenario brings maintenance to the top of priorities.

Whether it is corrective maintenance, predictive field maintenance or data-driven techniques in the directories’ agendas, maintenance is at the first place, now fundamental and essential.

The advantages and disadvantages of each of these strategies are now clear, just as it is increasingly clear that it is not a question of choosing one or the other, but a mix of each. Therefore, choosing the right balance between the different policies is the successful maintenance strategy.

Tamarri is always committed to identifying the most suitable and cutting-edge maintenance policy for your forklifts. 😉