Brake maintenance. Brakes and all related components represent one of the most importantl systems for the safety of any vehicle. What is their function and how to comply with adequate maintenance?

Brake maintenance. How do the brakes work and how is adequate maintenance complied with?

Brakes and attachments are fundamental components for moving vehicles. Their main aim is to convert the physical pressure exerted by the user on the brake pedal.

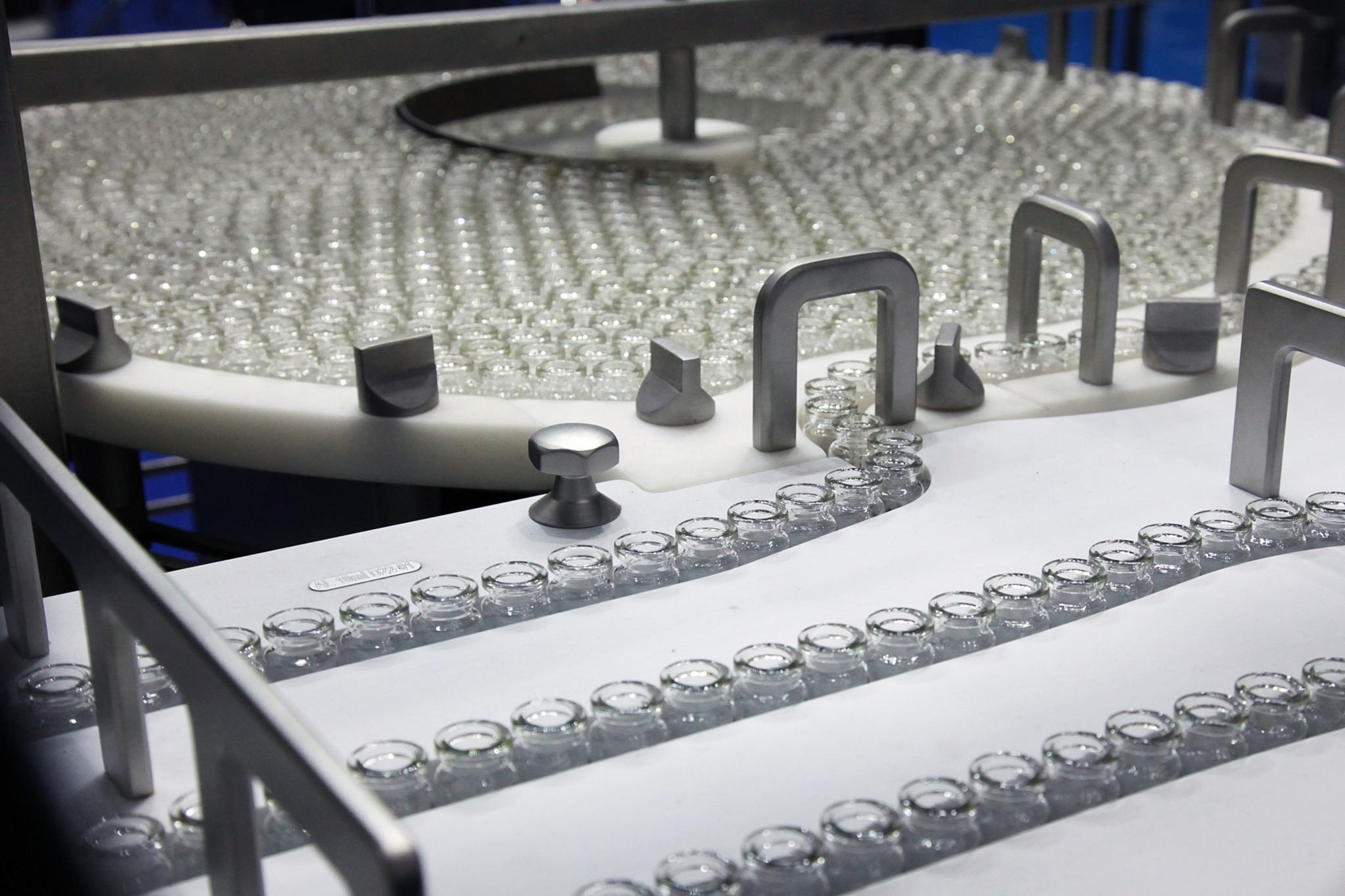

One of the fundamental components of the brake “system” is the master cylinder. It is easy to understand how much the quality of the brake pump is of primary importance to guarantee the best performance of the vehicle. The material with which a brake master cylinder is produced must be resistant to wear, must be safe and must guarantee very high standard levels.

In this regard, the use of cast iron and steel ensure the seal of the component over time. Aluminium could also be used, which make brake pumps lighter, but still resistant and able to guarantee the same performance.

Brake maintenance. How is security maintained

Tamarri S.r.l has always been involved in forklift safety. More and more frequently there are reports of accidents at work due to poor and “distracted” maintenance. Too often we are informed of accidents because maintenance has not been expected by competent and specialized personnel.

Regarding this, it is essential to do a regular and accurate monitoring the operation of the vehicle. A detailed analysis follows and the subsequent replacement of the worn part with the new one. To ensure that the analysis is always timely, many companies have already specialized in predictive analysis of the medium.

In the field of safety, why are the brake pumps of a forklift truck a fundamental element?

The brake pumps are very important, not only for the performance of the vehicle, but above all to safely manage the various activities.

Anyone who has had anything to do with forklifts will have noticed that. As time passes, there is less and less precise braking of the forklift. This is due to the loss of tightness of the internal rubber pads.

But why do the rubbers tend to decrease their hold? In several years, it is normal for the rubber pads to undergo normal wear. Furthermore, their duration is closely linked to the operator’s driving style.

For example, the habit of abruptly braking or the tendency to keep the foot lightly resting on the brake pedal, are all attitudes that represent a threat to the life of the rubber pads. If the grommets are worn out by some bad practice, the pump itself will also suffer the consequences.

Brake maintenance. What are the alarm bells for noticing brake wear?

It is not difficult to notice that the brakes are starting to wear out. Just keep an eye and monitor the vehicle often in order to check it. The punctuality of the forklift braking takes place in a decidedly less efficient way.

When the problem gets worse, you will notice that the brake pedal goes down empty. At this point the situation is worrying and the forklift is no longer safe: all that can be done is to stop it and ask for help from technical assistance.

How can the problem be solved?

It is essential not to underestimate the signs of malfunction and to know how to promptly remedy this malfunction. To prevent an inconvenience from turning into a serious risk for the operator and pedestrians, it is essential to resort to a specialized technician.

If the technician deems it necessary to replace the brake master cylinder, he will intervene directly at the customer’s site. In fact, the sealing rubbers are not easily replaceable by anyone because they are located within the single central block. Therefore it is an operation that requires about 2 or 3 hours of specialized work of a competent technician.

Forklift maintenance: a commitment to safety

Monitoring the operation of the forklift means making a daily commitment to ensure safety at work.

If you are looking for spare parts for the entire braking system, made to ensure resistance over time, excellent quality and delivered in a very short time (24/48 hours), Tamarri S.r.l is the company for you!

We have the best products on the market: safe, tested and CE marked, to guarantee our customers the highest quality standard in the industry. 🙂

This is how you can understand if there is room to use them even better to achieve maximum efficiency and therefore full customer satisfaction.

This is how you can understand if there is room to use them even better to achieve maximum efficiency and therefore full customer satisfaction.