Act plural. ”A dream you dream alone is only a dream, a dream you dream together is reality” – John Lennon

Act plural: collaboration and individuality

To collaborate means to actively participate, to achieve the accomplishment of a task or the performance of an activity. Within the company, collaboration is fundamental, as a synergistic relationship between two or more entities working together. The main goal is to produce something better than what could be done alone.

“Collaboration,” however, should not be at odds with “Individuality.”

One of the most famous quotes about teamwork, attributed to Chicago Bulls assistant coach Tex Winter, states: “there is no ‘I’ in ‘team.'” It is also said that the star of that team, Michael Jordan, replied: “but there is an ‘I’ in ‘win.'”

Fact: there is no room for individualism in collaboration. But successful collaboration requires room for individuality, now more than ever, since working alone has become almost impossible.

Even we ourselves individually have an “internal team,” and we are like a team composed of several different personalities, with different interests and desires, even divergent ones.

Act plural: collaboration and empathy

The goal of the I-professional’s day, for example, may not coincide with that of the I-in-family. Each person is at his or her best if he or she is in balance with his or her own life, and so to collaborate means to contribute to each other’s balance.

To collaborate, especially today when technologies give us access to increasingly effective and pervasive tools of connection (the magic – unthinkable 15 years ago – of a videocall) and sharing (the agility of a shared working document), it then becomes also and above all a matter of empathy, a delicate interconnection of “fractals” between our “internal team” and the real “external teams” of which we are part.

Sharing a project goal is important but collaborating with someone to ensure that both ours and his or her more “subtle” wants and needs are gratified and enhanced is what makes all the difference in our (and others’) work-life balance.

The advice: collaborate more and better, with others and with yourself. In the age of sharing, it is not only projects and goals that are “shared,” but also people, their values, their sensitivities, their multiple desires: commit to making sure that everything comes out better, not just the outcome of the project. Because if you learn to respect other people’s time, others will learn to respect yours.

Act plural: ask yourself the right questions

What can I do concretely to facilitate the collaboration in my team?

How do I consider the “vital” needs and desires of the people I collaborate with?

What questions should I ask my colleagues to stimulate and enrich my and their ideas?

How do I assess my level of active listening? And how could I improve it?

Training.

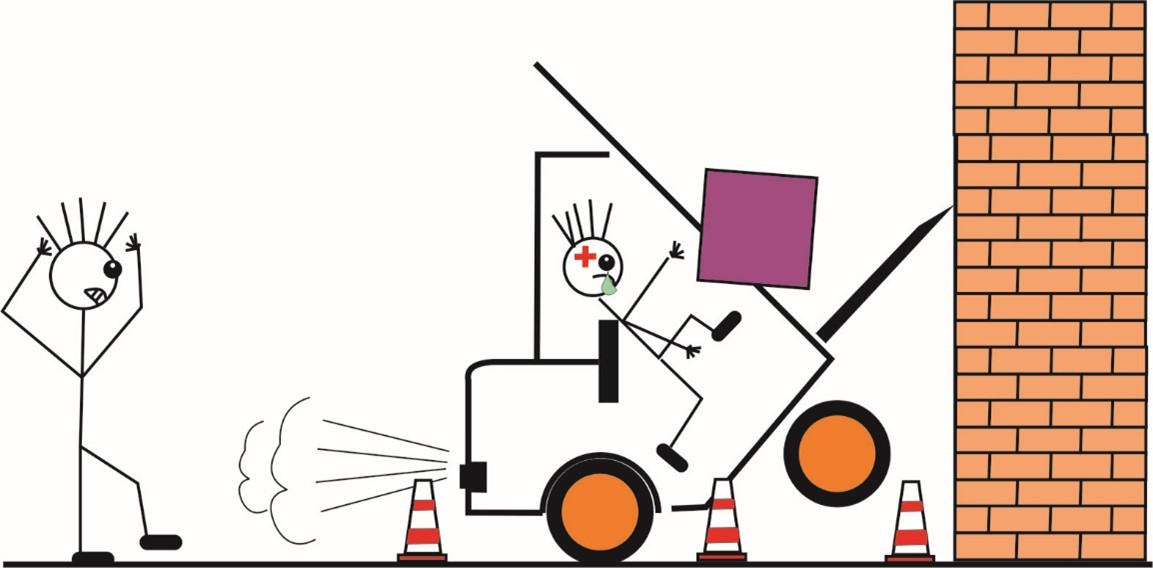

Workout #1 – Technology to collaborate

For one week, follow some simple rules to collaborate with technology, not only to achieve a given goal but also to respect other people’s needs:

– Transparency: share your schedule and have others share theirs with you.

– Cleanliness: as often as you can, put a maximum of 3 people in knowledge copy of an email, to avoid multiplication of information that might take unnecessary attention from others.

– Alignment: work on shared documents, to avoid unnecessary effort and wasted time (e.g., not to work in parallel on different versions of the same file).

– Accuracy: send targeted and concise emails, 5-10 lines maximum, with an unambiguous subject line and content structure that can be understood immediately.

– Empathy: send emails only at respectful hours (“sociable hours”), avoiding evenings and weekends, limiting yourself to communicating what the other person expects to know from you, or what is relevant to them.

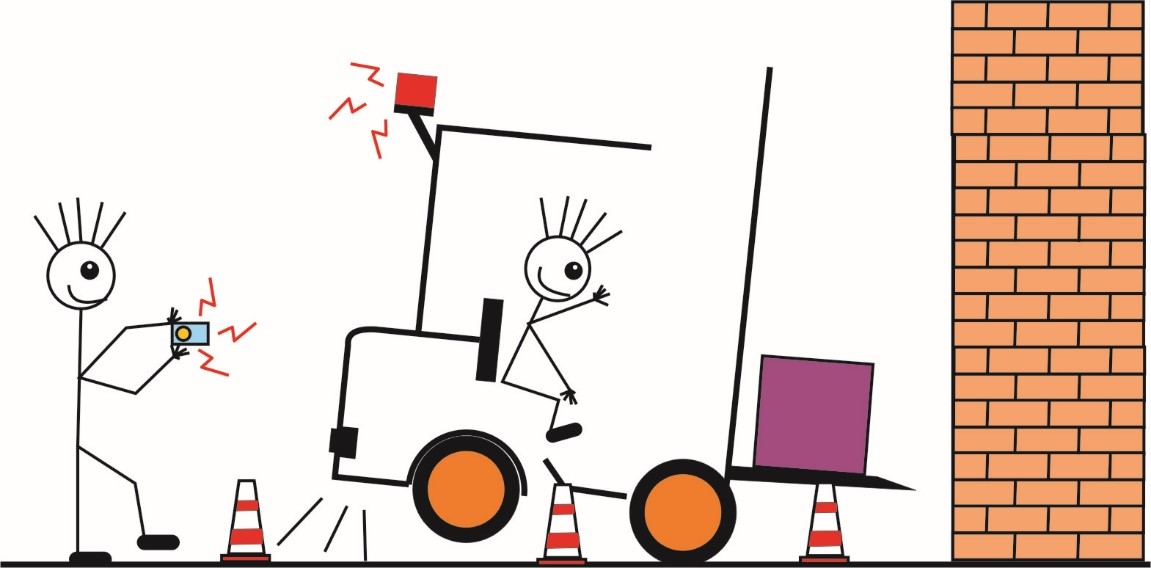

Workout #2 – Collective intelligence

For one week, follow 7 simple rules to collaborate and create innovative solutions together with others that are the result of collective intelligence.

– Instead of “the Devil’s,” be “the Angel’s Advocate”: don’t undermine others’ ideas but encourage them to generate new ones by “raising” on their own (avoid “yes, but…” and use “yes, and…”).

– Respect the brainstorming rules not only in dedicated sessions but in any time of sharing and exchanging ideas with other people. Separate the creative phase of idea generation (divergent phase) from judgment (convergent phase): when you are in the former, “surf” freely among other people’s ideas and, only in the latter, clearly and respectfully express your agreement or disagreement.

– Facilitate collective thinking: connect and relate your ideas to others and those of others to each other (“your idea makes me think of…”)

– Listen actively: ask your colleagues questions to understand better how and what they think. Involve, offer and ask for suggestions and advice.

– Relativize: start with the assumption that your beliefs are a point of view, not an unbreakable dogma. Question yourself, invite others to challenge your ideas, and continually look for cues to improve your thinking with the help of others.

– Eyes shut and focus on your breathing will help you get to sleep quickly.

– No distractions: the phone’s “flight mode” is your best friend!

Tamarri: technology for empathy! 😉