A broken forklift can cause production delays, increase maintenance costs and create dangerous working situations for operators. In this article, we will explore how a company specializing in forklift spare parts can help you keep your forklifts running smoothly, thanks to the supply of high-quality spare parts and technical support.

Forklifts: among the most important components of warehouse and production operations

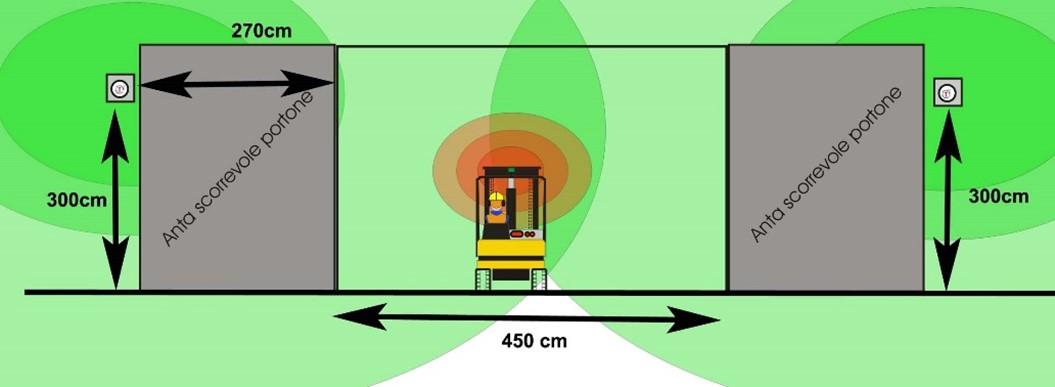

When forklifts break down, they can cause serious problems such as production delays and increased maintenance costs. Furthermore, a faulty forklift can be dangerous for operators and potentially cause injuries or damage to goods.

For all the above-mentioned reasons, having a reliable forklift parts supplier who can ensure the availability of high-quality spare parts to keep your forklifts in perfect condition and always moving is pf primary importance.

The advantages of a company specializing in forklift spare parts

A company specializing in forklift parts can offer a wide range of high-quality spare parts for all brands and models of forklifts. In addition to spare parts, these companies can also provide technical support, consultancy and training to ensure that operators are able to use forklifts safely and efficiently. Furthermore, by working with a specialist supplier, you can save time and money, as you will have access to a wide range of spare parts and technical assistance services.

What are the risks of using non-original spare parts

The use of non-original spare parts can cause safety problems, reduce the efficiency of the forklift and increase long-term maintenance costs.

These parts may not have been designed and manufactured to the same standards and specifications as original parts, which can cause problems such as premature wear and failure of forklift components.

How to choose a company specializing in spare parts for forklifts

When choosing a forklift parts supplier, it is important to look for a company that has extensive experience in the industry and offers a wide range of high-quality original spare parts. Make sure the company also provides technical support and technical assistance services to help you keep your fleet moving. Additionally, looking for a company that has helpful and reliable customer service that can answer all your questions and provide assistance in case of emergencies is always a reccomended choice.

How the forklift spare parts company can help you keep your forklifts efficient and always moving

Tamarri, a company specializing in forklift spare-parts, can help you keep your forklifts in perfect working order by providing a wide range of original, high-quality spare parts.

If you are looking for technical support to help you resolve common issues and avoid future problems, they are always available to offer advice on how to use the forklifts safely and efficiently, ensuring that operators are informed of the latest regulations and best practices.

Thanks to Tamarri S.r.l. you can provide maximum efficiency and safety of your forklifts, ensuring that your warehouse and manufacturing operations are able to run smoothly.