The earthmoving machinery sector, fundamental for the development of infrastructures and the implementation of various types of construction projects, is going through a phase of profound technological transformation. The integration of advanced technologies, from automation to artificial intelligence (AI), is redefining the limits of earthmoving operations, bringing substantial benefits in terms of operational efficiency, workplace safety and environmental sustainability.

Automations for greater safety and productivity

Automation technologies are revolutionizing the way earthmoving operations are managed, with a particular emphasis on safety and productivity in the workplace. Remote control systems allow operators to control machines from a safe location, dramatically reducing the risk of accidents and injuries during construction site activities. This is particularly crucial in high-risk situations or hazardous environments, where the operator’s physical presence could be at risk. The recent accidents at work that have crowded the news in recent months cannot leave us indifferent to this dramatic aspect.

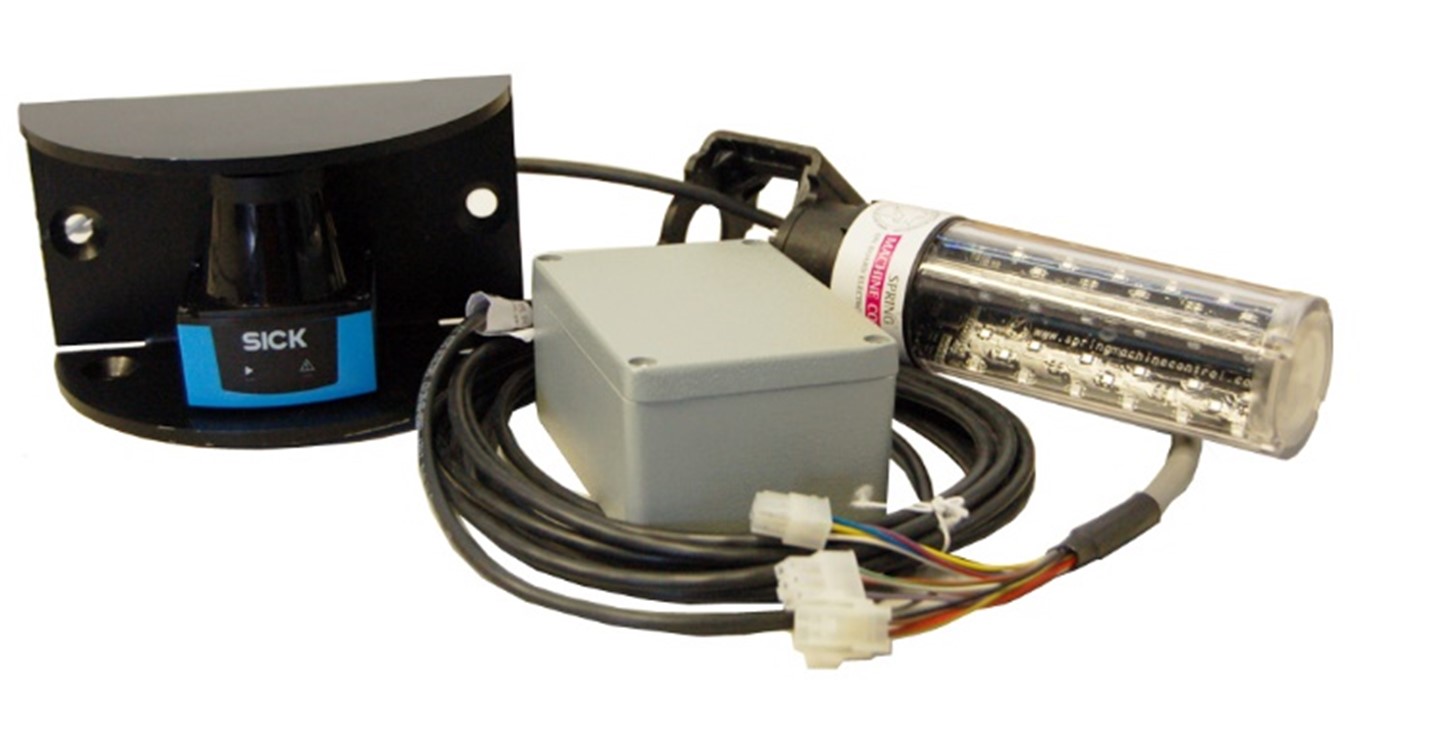

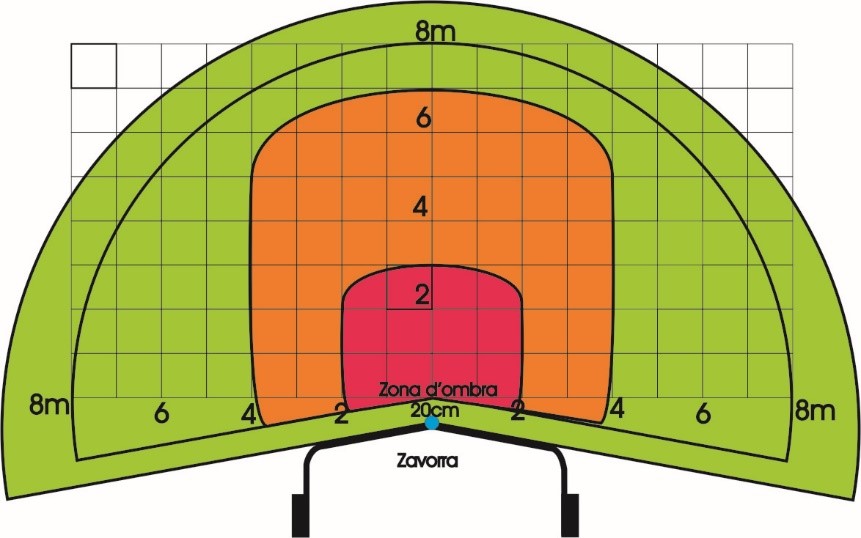

Sensors and Telemetry

The integration of advanced sensors and telemetry systems allows continuous collection of data on site conditions and machine performance. This data provides crucial information to optimize earthmoving operations, monitor machine health and prevent unexpected failures. Telemetry also allows real-time monitoring of machines remotely, allowing operators to intervene promptly in the event of anomalies or problems.

Autonomous driving for efficiency and precision

Autonomous driving represents another key innovation in the earthmoving machinery sector. This technology allows machines to autonomously navigate through a construction site by following predefined paths or dynamically adapting to environmental conditions. This not only reduces the dependence on human operators, who are nevertheless fundamental for the control and verification of the machines, but also improves the operational efficiency and precision of excavation, leveling and soil movement activities. Furthermore, autonomous driving allows for greater uniformity and consistency in the work carried out, minimizing errors and waste of resources.

Intelligent route management for resource optimization

Intelligent path management is another important application of automation technologies in the earthmoving machinery sector. These systems use real-time data to optimize machine routes, minimizing distance traveled and maximizing fuel efficiency. Additionally, intelligent route management takes into account variables such as construction site congestion, terrain conditions and access restrictions to ensure optimal workflow and equitable distribution of resources.

Artificial Intelligence and Machine Learning

The use of artificial intelligence and machine learning is revolutionizing the way earthmoving machinery is used and managed. AI algorithms analyze massive amounts of data to identify patterns and trends, improving the accuracy of digging, grading and earthmoving operations. Additionally, AI is used to optimize preventative maintenance, predicting downtime and proactively planning maintenance interventions.

Invest in training and infrastructure, constant evaluation and updating to ensure their correct functioning and maximize the benefits

In conclusion, the integration of automation and remote control technologies in the earthmoving machinery sector brings a series of significant benefits, including greater workplace safety, greater productivity and more efficient use of resources. However, it is important to note that these innovations require adequate investment in training and infrastructure, as well as continuous evaluation and updating to ensure their correct functioning and maximize the benefits for businesses and workers in the sector.

It is essential that companies in the sector remain updated on the latest technologies and adopt an innovative approach to the management of earthmoving machinery to remain competitive in an increasingly dynamic and competitive market.

The training

Training #1 – Technology for collaboration

For a week, follow some simple rules to use technology collaboratively, not only aimed at achieving a given goal, but also with respect to the needs of other people:

– Transparency: share your agenda and get others to share theirs with you.

– Cleaning: whenever you can, put a maximum of 3 people in carbon copy in an email, to avoid the multiplication of information that could draw unnecessary attention from others.

– Alignment: work on shared documents, to avoid unnecessary efforts and waste of time (for example, to avoid working in parallel on different versions of the same file).

– Accuracy: send targeted and concise emails, 5-10 lines maximum, with an unambiguous subject and a content structure that is understandable at a glance.

– Empathy: send emails only during respectful hours (“sociable hours”), avoiding evenings and weekends, limiting yourself to communicating what the other person expects to know from you, or what is relevant to them.

Training #2 – Collective intelligence

For a week, follow 7 simple rules to collaborate and create innovative solutions together with others, the result of collective intelligence.

– Don’t undermine other people’s ideas, but encourage them to generate new ones by “launching” on theirs (avoid “yes, but…” and use “yes, and…”).

– Respect the rules of brainstorming, not only in dedicated sessions, but in every moment of sharing and exchanging ideas with other people. Separate the creative phase of generating ideas (divergent phase) from the judgment (convergent phase): when you are in the first, “surf” freely among the ideas of others and, only in the second, express your consent or dissent with clarity and respect.

– Facilitates collective thinking: connect and relate your ideas to those of others and those of others to each other (“your idea makes me think of…”)

– Listen actively, ask others questions to better understand how and what they think. Engage, offer and ask for suggestions and advice.

– Relativize: start from the assumption that your beliefs are a point of view, not a mandatory dogma. Question yourself, invite others to challenge your ideas, and continually look for ideas to improve your thinking with the help of others.

– Keeping your eyes closed and paying attention to your breathing will help you fall asleep quickly.

– No distractions: your phone’s “flight mode” is your best friend!

Tamarri: for a technology dedicated to empathy! 😉